The liquid natural gas (LNG) industry is demanding, requires premium quality, and is constantly growing. As an answer to changes in global energy supply chains and stricter environmental regulations that are less favourable to coal, new LNG tanker orders keep breaking records.

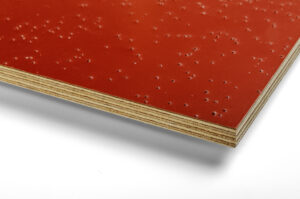

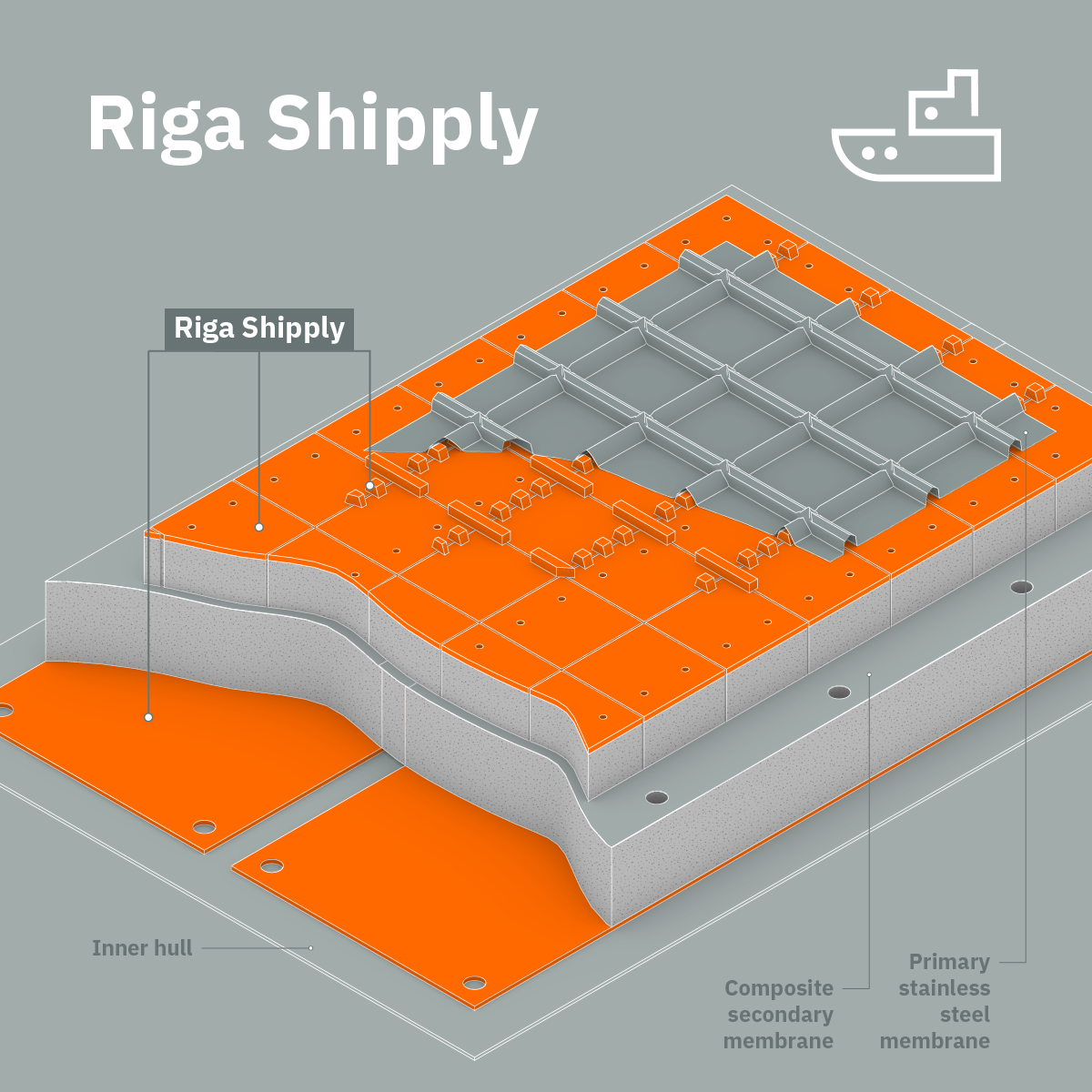

This year Latvijas Finieris marks the 20th anniversary since sealing the first order to supply LNG tanker builders. Riga Shipply, a premium-class birch plywood specially designed for LNG cargo containment systems, is produced in five mills of Latvijas Finieris in Latvia and Estonia, all certified to meet the requirements of classification societies.

Increasing volumes to meet the demand

When looking globally, the figures for new orders of LNG tankers in 2022 were more than double compared to the results of 2021. Previously a global breakthrough in new LNG tanker orders was experienced in 2014.

As an answer to the demand, the volumes of Riga Shipply birch plywood supplied to LNG takes a significant share of the total production volumes of 2023. The primary market remains South Korea with its highly developed LNG industry and its giants – Samsung Heavy Industries and Hyundai Heavy Industries – both long-time Latvijas Finieris and Riga Wood cooperation partners.

It is expected to have a high demand for new LNG tankers production for another two to three years.

Wide application in the sea transport sector

Even though the main Riga Shipply application is in building LNG tankers, Riga Wood birch plywood products are applied in other highly specialised ships – LNG fuel tanks, ethane tankers and floating storage regasification units (LNG FSRU), as well as for LNG ground storage tanks on shore. Other Riga Wood birch plywood products, like Riga Mel and Riga Form, are used in more commercial projects – for interior and exterior solutions on yachts and boats. Riga Grip with a special anti-slip epoxy coating and other customised solutions with a grooved surface (e.g. grading) and special holes for air circulation are used for refrigerator ships.